"THE ART AND ADVANTAGES OF PRESSURE DIE CASTING"

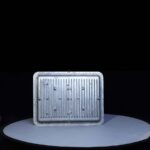

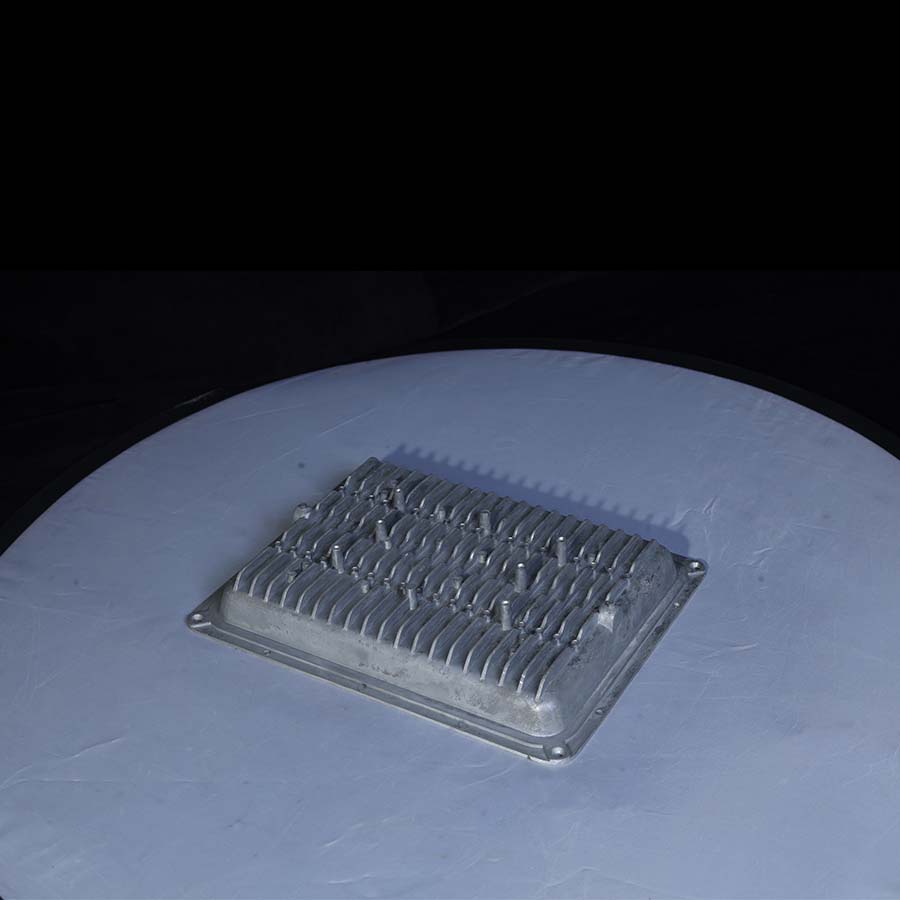

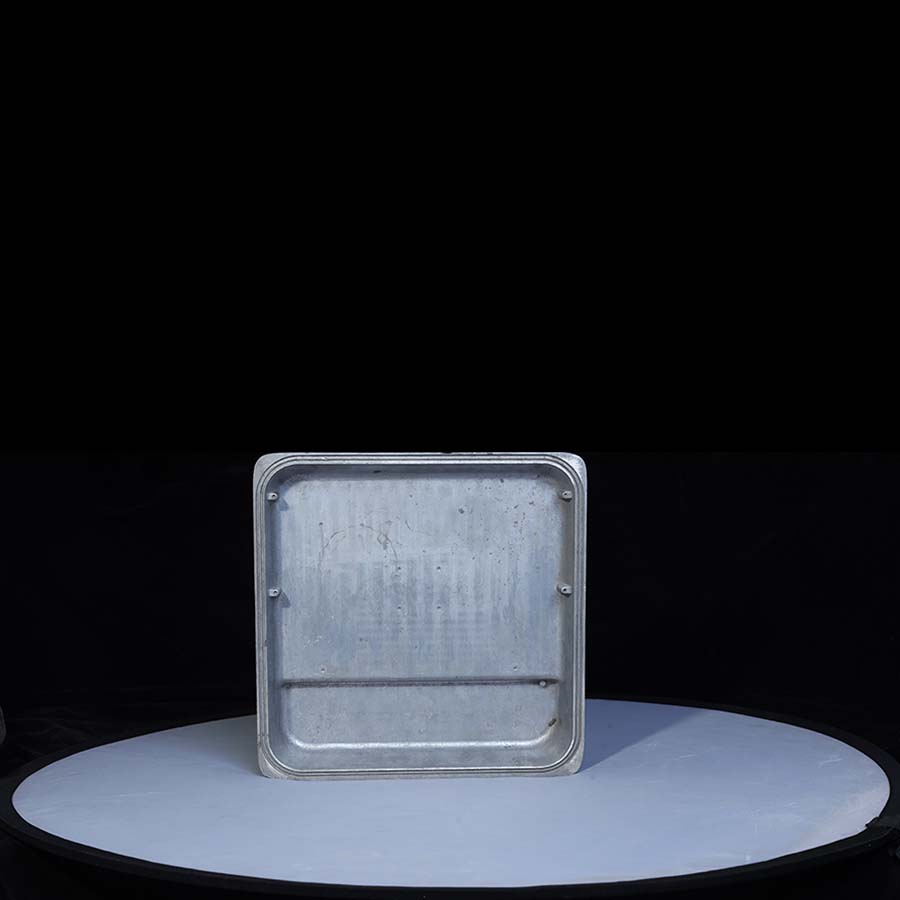

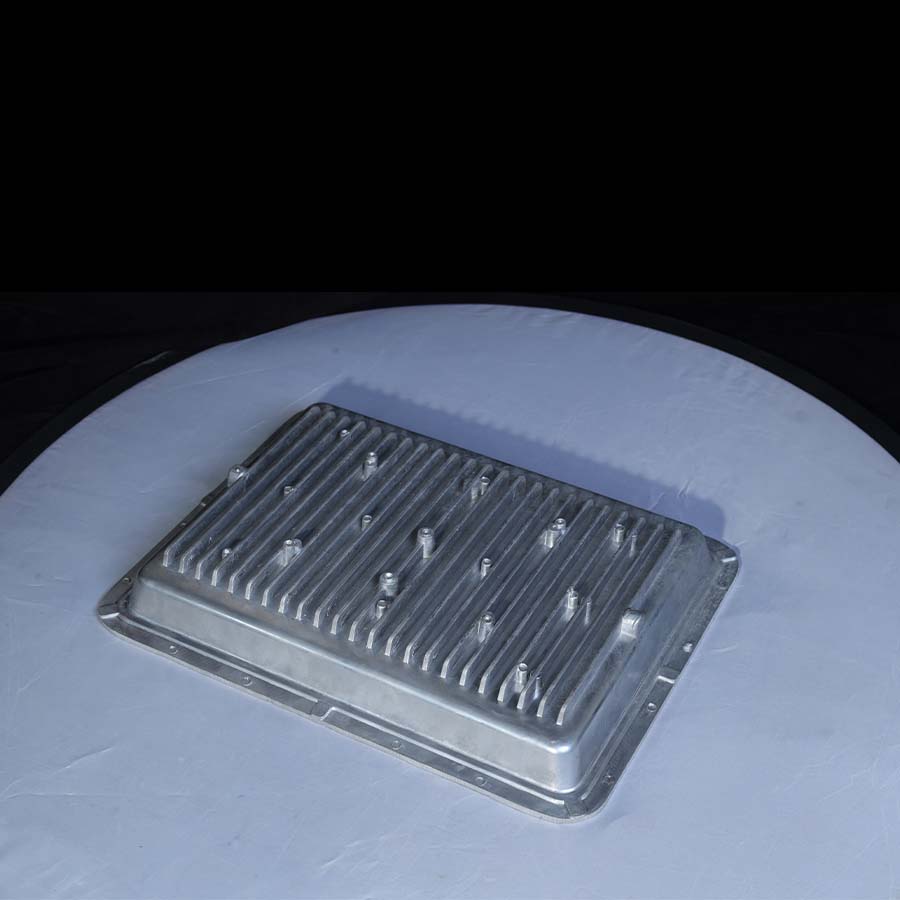

“Embark on a journey of precision with our cutting-edge Pressure Die Casting. At Shree Bhagyalaxmi Industries(SB Allu Cast), we master the art of creating intricate components through this advanced technique. Our process involves injecting molten metal into high-quality steel molds under substantial pressure, ensuring impeccable detail and minimal porosity. The advantages are evident — from exceptional dimensional accuracy and superior surface finish to the ability to produce complex geometries efficiently. Trust us to elevate your manufacturing standards with our commitment to excellence, innovation, and the unmatched precision offered by Pressure Die Casting.”

OVERVIEW

Precision in Action:

Pressure Die Casting is a sophisticated metal casting process known for its precision and efficiency. At Shree Bhagyalaxmi Industries(SB Allu Cast), we bring artistry to every step of this technique.

Process Insights:

Molten metal, typically aluminum or zinc, is injected into a steel mold under high pressure. This pressure ensures that the molten metal fills every intricate detail of the mold, resulting in precise and high-quality components.

Advantages:

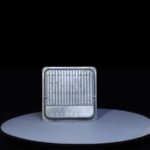

Exceptional Detail:

Pressure Die Casting achieves intricate and complex geometries with remarkable detail.

Dimensional Accuracy:

The process ensures tight tolerances, providing components with excellent dimensional accuracy.

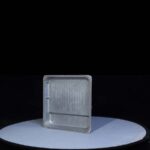

Reduced Porosity:

High pressure minimizes porosity in the final casting, enhancing structural integrity.

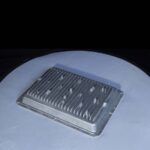

Efficient Production:

Rapid cycle times make Pressure Die Casting suitable for high-volume production runs.

Fine Surface Finish:

Castings exhibit a smooth and fine surface finish, often eliminating the need for additional finishing steps.

Material Versatility:

Suitable for a range of alloys, including aluminum, zinc, and magnesium.

Cost-Effective:

The efficiency of the process and reduced need for post-casting operations contribute to overall cost-effectiveness.

Applications:

Pressure Die Casting finds applications across industries, especially in automotive, aerospace, and electronics, where intricate parts and high precision are essential.

Shree Bhagyalaxmi Industries(SB Allu Cast) Expertise:

Our commitment to excellence ensures that Pressure Die Casting at Shree Bhagyalaxmi Industries (SB Allu Cast) is a fusion of art and cutting-edge technology, delivering components that meet the highest standards of quality and precision.

Carbon black Dispersion Tester:

Micro Projection Doom Size 6”Dia.

Magnification Range 100X, 200X,400X

Hot Plate 7” Dia

Temp. Range 300˚C.

Computer Interfacing System Window Base Software

Power Supply 230V, 1 Phase, 50HZ

Pressure Die Casting is a metal casting process where molten metal, often aluminum or zinc, is injected into a steel mold under high pressure. This results in precise and detailed components, making it a preferred method for various industries.

Unlike gravity die casting or sand casting, pressure die casting utilizes high pressure to force molten metal into the mold. This results in superior detail, reduced porosity, and high-dimensional accuracy, making it suitable for intricate components.

Pressure Die Casting provides several advantages, including exceptional detail, tight dimensional accuracy, reduced porosity, and efficient production cycles. Its versatility in handling various alloys makes it a cost-effective solution for high-volume production.

Pressure Die Casting is widely employed in automotive, aerospace, electronics, and other industries where precision and efficiency are crucial. It is the preferred method for producing complex components, such as engine parts, electronic housings, and structural components.

Shree Bhagyalaxmi Industries specializes in the art of Pressure Die Casting, ensuring excellence in every cast component.

For More details & Information