"Precision Unleashed: Gravity Die Casting Excellence"

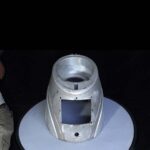

Experience the epitome of precision with “Precision Unleashed: Gravity Die Casting Excellence” at Shree Bhagaylaxmi Industries (SB Allu Cast). Our cutting-edge facilities and skilled artisans converge to deliver gravity die castings of unparalleled quality. This process ensures intricate designs, impeccable finishes, and minimized porosity in the final products. From intricate components to complex parts, our gravity die casting expertise guarantees top-notch results. Trust us to elevate your manufacturing standards, providing efficient and accurate solutions. Embrace excellence with Shree Bhagaylaxmi Industries(SB Allu Cast) – where precision meets innovation in every gravity die casting endeavor, setting new benchmarks in the industry.

OVERVIEW

Gravity die casting is a highly efficient metal casting process that involves the use of a permanent mold made of steel or iron. Unlike other casting methods, gravity die casting relies on the force of gravity to fill the mold cavity with molten metal. This process is ideal for producing high-quality, intricate components with excellent dimensional accuracy.

Key features of gravity die casting include:

- Permanent Molds: The molds used in gravity die casting are reusable and can withstand multiple casting cycles, making them cost-effective and suitable for mass production.

- Gravity-Fed Metal: Molten metal is poured into the mold, allowing gravity to fill the cavity and form the desired shape. This results in a smoother and denser casting with minimal porosity.

- Precision and Detail: Gravity die casting is known for its ability to produce intricate and complex parts with tight tolerances. This makes it a preferred choice for components where precision is crucial.

- Alloy Versatility: Gravity die casting accommodates a wide range of alloys, including aluminum, zinc, and copper-based alloys, offering flexibility in material selection based on the application requirements.

- Surface Finish: The process yields castings with a fine surface finish, reducing the need for additional finishing operations.

- Cost-Effective for Large Runs: Gravity die casting is particularly cost-effective for large production runs due to the reusable nature of the molds and the relatively fast casting cycle.

Shree Bhagaylaxmi Industries(SB Allu Cast) specializes in Gravity Die Casting, ensuring superior quality and precision in every component produced. Our commitment to excellence makes us a trusted partner for industries requiring high-performance castings.

Carbon black Dispersion Tester:

Micro Projection Doom Size 6”Dia.

Magnification Range 100X, 200X,400X

Hot Plate 7” Dia

Temp. Range 300˚C.

Computer Interfacing System Window Base Software

Power Supply 230V, 1 Phase, 50HZ

Gravity die casting is a metal casting process where molten metal is poured into a reusable permanent mold, typically made of steel or iron. Unlike other casting methods, gravity is utilized to fill the mold cavity, resulting in high-precision components with a smooth finish.

Gravity die casting offers several advantages, including excellent dimensional accuracy, superior surface finish, and the ability to produce intricate and complex parts. The process is cost-effective for large production runs due to reusable molds and efficient casting cycles.

Gravity die casting accommodates a variety of materials, with aluminum, zinc, and copper-based alloys being commonly used. The versatility in material selection allows for the production of components tailored to specific application requirements.

- Unlike processes such as sand casting or investment casting, gravity die casting relies on gravity to fill the mold cavity. This results in a smoother and denser casting with minimal porosity. The use of permanent molds distinguishes gravity die casting from methods that involve disposable molds.

Shree Bhagyalaxmi Industries is your expert partner in Gravity Die Casting, providing precision, efficiency, and quality in every casting project.

For More details & Information