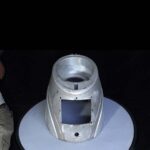

"Aluminum Castings For Railways"

Specifications for aluminum castings used in railway applications may vary depending on the specific component and its intended use. Here are some common specifications that may be applicable:

OVERVIEW

- Material: Aluminum alloys such as A356, A357, or A380 are often used for railway castings due to their lightweight, corrosion resistance, and strength.

- Dimensional Tolerances: Precision is important for railway components to ensure proper fit and functionality. Tight dimensional tolerances may be specified for critical dimensions such as mounting points, mating surfaces, and clearances.

- Surface Finish: The surface finish of aluminum castings for railway applications should be smooth and free from defects to ensure proper operation and longevity. Surface finishes such as shot blasting, sandblasting, or painting may be specified based on the requirements of the component.

- Mechanical Properties: Mechanical properties such as tensile strength, yield strength, elongation, and impact resistance may be specified to ensure the structural integrity and performance of the casting under railway operating conditions.

- Corrosion Resistance: Aluminum castings for railway applications should have good corrosion resistance to withstand exposure to harsh environmental conditions, including moisture, salt, and chemicals.

- Fatigue Resistance: Components subjected to cyclic loading, such as bogie components or structural elements, may require specific fatigue resistance properties to ensure long-term durability and safety.

- Non-Destructive Testing (NDT): Depending on the criticality of the component, NDT methods such as ultrasonic testing, X-ray inspection, or dye penetrant inspection may be required to detect defects and ensure the integrity of the castings.

- Compliance: The specifications should comply with relevant industry standards and regulations, such as EN 15085 for welding of railway vehicles and components, or specific standards set by railway authorities or manufacturers.

- Packaging and Labeling: Castings should be packaged and labeled appropriately to prevent damage during transit and to ensure traceability throughout the supply chain.

- Documentation: Comprehensive documentation, including material certificates, inspection reports, and quality control records, should accompany the aluminum castings to provide assurance of their quality and compliance with specifications.

It’s important to collaborate closely with railway engineers, designers, and manufacturers to ensure that the specifications for aluminum castings meet the specific requirements of the railway application and comply with relevant standards and regulations.

- Aluminum alloy type (e.g., A356, A357) suitable for casting with appropriate mechanical properties.

- Compliance with industry standards for aluminum alloys used in railway applications.

For More details & Information