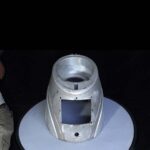

"Aluminum Castings For Material Handling Equipment's"

Aluminum castings are widely used in material handling equipment due to their lightweight yet durable properties. Here’s why they’re a popular choice:

OVERVIEW

- Lightweight: Aluminum is significantly lighter than steel, making it ideal for components in material handling equipment where weight is a concern. This allows for easier maneuverability and reduced energy consumption.

- Strength: Despite its lightweight nature, aluminum offers good strength-to-weight ratio. It can withstand the rigors of material handling applications without compromising on performance.

- Corrosion Resistance: Aluminum has excellent corrosion resistance, especially when properly treated or coated. This ensures longevity and reduces maintenance requirements, which is crucial for equipment used in various environments.

- Machinability: Aluminum is relatively easy to machine, allowing for complex designs and precise components. This is advantageous for creating custom parts tailored to specific material handling needs.

- Thermal Conductivity: Aluminum has high thermal conductivity, which can be beneficial in applications where heat dissipation is important, such as in motor housings or brake components.

- Recyclability: Aluminum is highly recyclable, making it environmentally friendly. Using aluminum castings in material handling equipment supports sustainability efforts and reduces the overall carbon footprint of the equipment.

For More details & Information