- Aluminum Alloy Selection:

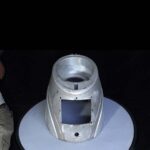

- Specify an aluminum alloy suitable for casting with properties such as high strength, corrosion resistance, and thermal stability.

- Commonly used alloys include A356, A380, or specialized alloys designed for casting compressor valve components.

- Dimensional Accuracy:

- Tight dimensional tolerances to ensure precise fit and alignment with other valve components and the compressor assembly.

- Specifications for critical dimensions such as valve seat diameter, stem diameter, and overall valve geometry.

- Surface Finish:

- Specify the desired surface finish to minimize friction, wear, and leakage.

- Surface treatment options may include shot blasting, polishing, or specialized coatings to enhance durability and sealing properties.

- Mechanical Properties:

- Define target mechanical properties based on the specific application and operating conditions of the compressor valves.

- Specifications for tensile strength, yield strength, elongation, hardness, and fatigue resistance may be required to ensure long-term reliability.

- Chemical Composition:

- Control the chemical composition of the aluminum alloy to meet performance and regulatory requirements.

- Ensure compliance with industry standards and regulations governing material composition and environmental considerations.

- Heat Treatment:

- Specify any required heat treatment processes such as solution annealing or aging to optimize the mechanical properties and dimensional stability of the castings.

- Non-Destructive Testing (NDT):

- Mandate the use of NDT techniques such as X-ray inspection, ultrasonic testing, or dye penetrant testing to detect internal defects and ensure casting integrity.

- Corrosion Resistance:

- Ensure that the aluminum castings exhibit excellent corrosion resistance to withstand exposure to moisture, gases, and chemicals encountered in compressor applications.

- Precision Machining Allowances:

- Provide allowances for machining critical features and tolerances, if necessary, to achieve the required dimensional accuracy and surface finish.

- Quality Control and Certification:

- Implement rigorous quality control measures throughout the casting process to ensure consistency and reliability.

- Obtain certifications and documentation attesting to material traceability, conformance to specifications, and compliance with industry standards (e.g., ISO 9001).

- Packaging and Handling:

- Specify appropriate packaging methods to prevent damage during transportation and storage.

- Ensure proper labeling and identification for inventory management and traceability.

- Documentation:

- Prepare comprehensive documentation including material certificates, inspection reports, quality control records, and technical specifications.

- Include detailed drawings or CAD models specifying dimensional, material, and surface finish requirements for the compressor valves.

By adhering to these specifications, manufacturers can produce high-quality aluminum castings that meet the demanding performance and reliability standards required for compressor valves in various applications, including industrial compressors, HVAC systems, and refrigeration units.