- Aluminum Alloy Selection:

- Choose an aluminum alloy suitable for casting with properties such as high strength, good machinability, and resistance to corrosion and wear.

- Common alloys used include A356, A380, or specific proprietary alloys designed for casting compressor parts.

- Dimensional Accuracy:

- Tight dimensional tolerances to ensure proper fit and function within the compressor assembly.

- Precision casting techniques to achieve accurate dimensions and minimize machining requirements.

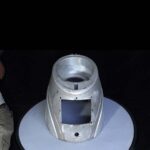

- Surface Finish:

- Smooth surface finish to reduce friction and wear, improving the efficiency and lifespan of compressor parts.

- Surface treatment options like shot blasting, polishing, or coating for enhanced durability and corrosion resistance.

- Mechanical Properties:

- Target mechanical properties such as tensile strength, yield strength, elongation, and hardness to withstand the operational stresses and pressures encountered in compressor applications.

- Consideration of fatigue resistance for components subjected to cyclic loading.

- Chemical Composition:

- Control of alloy composition to meet specific requirements for strength, ductility, and thermal stability.

- Compliance with industry standards and regulations regarding material composition.

- Heat Treatment:

- Heat treatment processes such as solution annealing or aging to enhance the mechanical properties and stability of the castings.

- Non-Destructive Testing (NDT):

- Implementation of NDT techniques like X-ray inspection, ultrasonic testing, or dye penetrant testing to detect internal defects and ensure casting integrity.

- Compatibility with Working Fluids:

- Resistance to corrosion or degradation when exposed to the working fluids (e.g., air, refrigerants) and operating conditions of the compressor.

- Precision Machining Allowances:

- Provision of adequate material allowances for machining critical features and tolerances, if required.

- Quality Control and Certification:

- Rigorous quality control measures throughout the casting process to ensure consistency and reliability.

- Certification of materials, processes, and compliance with industry standards (e.g., ISO 9001) for quality management systems.

- Documentation:

- Comprehensive documentation including material certificates, inspection reports, and quality control records.

- Technical drawings or specifications detailing dimensional, material, and surface finish requirements.

By adhering to these specifications, aluminum castings for compressor parts can meet the demanding performance and reliability standards required in various compressor applications, including industrial compressors, HVAC systems, and refrigeration units.