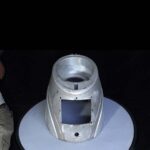

"Aluminum Castings With Gun Metal Inserts"

Specifications for aluminum castings with gun metal inserts are crucial to ensure the integrity, functionality, and compatibility of the finished product. Here’s a detailed outline of potential specifications:

OVERVIEW

- Aluminum Alloy Selection:

- Choose an aluminum alloy suitable for casting with properties such as good fluidity, thermal conductivity, and compatibility with gun metal inserts.

- Commonly used alloys include A356, A380, or specific alloys designed for casting with inserts.

- Gun Metal Insert Material:

- Specify the material composition and properties of the gun metal inserts, typically composed of bronze or brass alloys.

- Ensure compatibility between the aluminum casting and the gun metal insert in terms of thermal expansion, corrosion resistance, and mechanical properties.

- Dimensional Accuracy:

- Tight dimensional tolerances to ensure precise fit and alignment between the aluminum casting and the gun metal insert.

- Specifications for insert location, depth, and interference fit requirements.

- Insert Placement and Design:

- Design the casting mold to accommodate the placement of gun metal inserts during the casting process.

- Ensure proper gating and riser design to prevent defects and achieve uniform filling around the inserts.

- Surface Finish:

- Specify the desired surface finish for both the aluminum casting and the gun metal inserts to meet functional and aesthetic requirements.

- Surface treatment options may include shot blasting, polishing, or plating for enhanced durability and appearance.

- Mechanical Properties:

- Define target mechanical properties for both the aluminum casting and the gun metal inserts to ensure compatibility and performance under load.

- Specifications for tensile strength, yield strength, hardness, and wear resistance may be required.

- Corrosion Resistance:

- Ensure that both the aluminum casting and the gun metal inserts exhibit adequate corrosion resistance to withstand exposure to environmental elements and operating conditions.

- Specify corrosion-resistant coatings or treatments as needed to extend the service life of the components.

- Assembly Requirements:

- Specify assembly methods and procedures for inserting and securing the gun metal inserts into the aluminum castings.

- Ensure proper bonding or mechanical retention to prevent loosening or detachment during service.

- Quality Control and Inspection:

- Implement quality control measures to verify the integrity of the casting and the proper installation of the gun metal inserts.

- Conduct inspections, including visual, dimensional, and non-destructive testing, to detect defects and ensure conformance to specifications.

- Documentation:

- Prepare comprehensive documentation including material certificates, inspection reports, quality control records, and assembly instructions.

- Include detailed drawings or CAD models specifying dimensional, material, and assembly requirements for the aluminum castings with gun metal inserts.

By adhering to these specifications, manufacturers can produce high-quality aluminum castings with gun metal inserts that meet the functional, aesthetic, and performance requirements of various applications, including machinery, equipment, and architectural components.

For More details & Information