Pressure Die Casting Manufacturers

Pressure die casting is a process that involves injecting molten metal into a mold under high pressure to create precise, durable components. Widely used in industries ranging from automotive to aerospace and industrial machinery, this technique ensures the production of parts with excellent surface finish and mechanical properties. In this blog post, we explore the key advantages of pressure die casting, the industries that benefit from it, and how to choose the best pressure die casting manufacturers for your business.

What is Pressure Die Casting?

Pressure die casting is a highly efficient and precise manufacturing process that uses high-pressure injection to force molten metal into a mold cavity. The result is a metal part with high accuracy and smooth surfaces, free from imperfections. This process is commonly used with metals such as aluminum, zinc, and magnesium alloys. The process is ideal for creating complex components that require tight tolerances, durability, and lightweight properties.

The Process of Pressure Die Casting

The process begins by preparing the die, or mold, typically made from high-strength steel. The mold is preheated to ensure proper filling during injection. Molten metal is then injected into the mold under high pressure—sometimes up to 30,000 psi—filling the cavity completely and ensuring precision. Once the molten metal cools and solidifies, the mold is opened, and the finished component is removed.

Advantages of Pressure Die Casting

Pressure die casting offers several key advantages that make it an ideal choice for manufacturing metal components:

- Precision and Accuracy: The high-pressure injection ensures that even complex molds are filled completely, resulting in parts with high dimensional accuracy and consistency.

- Superior Surface Finish: Components produced through pressure die casting have a smooth surface finish, reducing the need for additional machining or finishing.

- Strength and Durability: The high-density castings produced through this process are strong, durable, and resistant to wear, making them suitable for demanding applications.

- Complex Geometries: The ability to create intricate and detailed designs with minimal tooling cost is one of the main benefits of pressure die casting. Thin walls and complex shapes are easily achieved.

Industries That Benefit from Pressure Die Casting

Pressure die casting is used across a wide variety of industries due to its ability to produce high-quality, durable components. Here are some industries that benefit from this manufacturing technique:

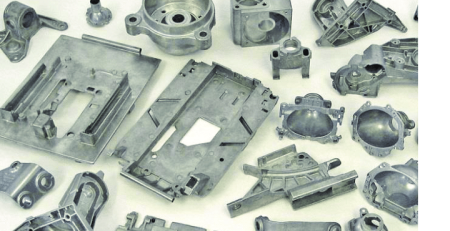

1. Automotive Industry

The automotive industry is one of the largest sectors that rely on pressure die casting for producing components such as engine blocks, cylinder heads, transmission housings, and suspension parts. This method enables the production of lightweight yet durable parts that help reduce the overall weight of vehicles while ensuring high performance and safety.

2. Aerospace

In aerospace, parts need to meet strict safety and performance standards. Pressure die casting helps create lightweight components, such as turbine housings, brackets, and structural elements, from high-strength materials like aluminum and magnesium alloys. These alloys are chosen for their excellent strength-to-weight ratio, which is critical in aerospace applications.

3. Electronics and Electrical

Pressure die casting plays a crucial role in the production of electrical enclosures, connectors, heat sinks, and other components used in electronics. The process ensures that parts have high precision and excellent thermal conductivity, making them perfect for cooling and protecting sensitive electronic devices.

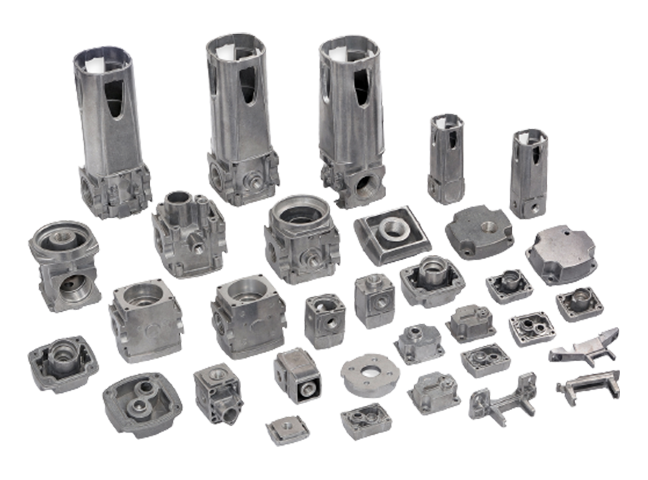

4. Industrial Machinery

For heavy-duty machinery and industrial equipment, parts must be durable and able to withstand extreme conditions. Pressure die casting is used to manufacture pump housings, compressor bodies, valve bodies, and other critical components in industrial machinery. These parts benefit from the strength and durability offered by the pressure die casting process.

How to Choose the Best Pressure Die Casting Manufacturer

When selecting a pressure die casting manufacturer, there are several important factors to consider to ensure that you receive high-quality components at competitive prices. Below are some key considerations for choosing the right manufacturer:

1. Experience and Expertise

Choose a manufacturer with a proven track record in pressure die casting. Experience matters when it comes to handling complex designs, tight tolerances, and specific materials. A manufacturer with years of experience will have the knowledge necessary to meet your specific requirements and offer guidance throughout the process.

2. Quality Control

Quality control is vital in pressure die casting. The manufacturer should have a comprehensive quality assurance system in place, which includes regular inspections, testing, and adherence to industry standards. Look for certifications such as ISO 9001, which indicates that the manufacturer meets international quality standards.

3. Technology and Equipment

The technology used by the manufacturer plays a crucial role in ensuring that your components are produced accurately and efficiently. Look for manufacturers who invest in state-of-the-art equipment, such as advanced die casting machines and automated processes, to ensure consistency and precision.

4. Material Expertise

Different alloys offer different mechanical properties, such as strength, corrosion resistance, and weight. A good manufacturer should have expertise in working with a variety of materials and be able to suggest the best alloy for your application. Aluminum, zinc, magnesium, and copper alloys are some of the most commonly used materials in pressure die casting.

5. Lead Time and On-Time Delivery

Timely delivery is crucial for meeting production deadlines. Ensure that the manufacturer can provide reliable lead times and deliver your components on schedule. A reliable manufacturer will help avoid costly delays and keep your project on track.

6. Competitive Pricing

Price is always a factor in any manufacturing decision. While quality should always come first, it’s important to find a manufacturer who offers competitive pricing. Manufacturers with high-volume production capabilities can often provide better pricing, especially for large orders.

Why Pressure Die Casting Manufacturers Are Essential for Modern Industry

Pressure die casting manufacturers play a vital role in ensuring that industries receive the high-quality, reliable components they need. These manufacturers are experts in producing parts that meet strict design and performance requirements, often within tight tolerances. By partnering with a reputable manufacturer, you can ensure that your products meet the high standards of durability, strength, and precision required in various industries.

Pressure Die Casting in the Green Economy

With growing concerns over environmental impact, pressure die casting is becoming an increasingly important process in sustainable manufacturing. The use of aluminum, for example, helps reduce the carbon footprint of products, as aluminum is a lightweight material that contributes to energy savings, especially in automotive and aerospace industries. Additionally, many pressure die casting manufacturers are adopting more environmentally-friendly practices, such as recycling scrap metal and reducing energy consumption.

Conclusion

Pressure die casting is an indispensable method for producing high-quality, durable, and precise components across many industries. Whether for automotive, aerospace, electronics, or industrial machinery, pressure die casting manufacturers provide reliable solutions that help businesses create complex parts with minimal lead time and cost. By choosing an experienced, high-quality pressure die casting manufacturer, you can ensure that your products meet the highest standards of precision, durability, and performance.

Leave a Reply