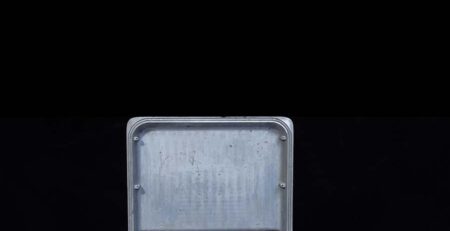

Aluminum gravity heavy die casting

Aluminum Gravity Heavy Die Casting: Precision Engineering by Shree Bhagyalaxmi Industries (SB Allu Cast)

“Shree Bhagyalaxmi Industries (SB Allu Cast), located in Ahmedabad, Gujarat, India, specializes in high-quality aluminum gravity heavy die casting solutions. With advanced technology and skilled craftsmanship, we offer precise and durable aluminum castings for various industries. Explore our expertise, processes, and commitment to excellence.”

Introduction to Aluminum Gravity Heavy Die Casting

Aluminum gravity heavy die casting is a specialized manufacturing process used to produce high-precision aluminum castings. At Shree Bhagyalaxmi Industries (SB Allu Cast), we utilize this technique to create strong, lightweight, and durable aluminum products for a wide range of industries, including automotive, aerospace, and machinery. Located in Ahmedabad, Gujarat, our company has built a solid reputation for delivering high-quality castings that meet the exacting standards of our clients.

Key Features and Benefits of Aluminum Gravity Die Casting

- High Precision and Accuracy

Aluminum gravity die casting provides exceptional dimensional accuracy, making it perfect for industries that demand precision in their parts, such as automotive and aerospace. - Cost-Effective Production

The gravity casting process offers a cost-effective solution, especially for medium to high-volume production runs. It reduces the need for secondary operations. - Durability and Strength

Castings produced through this method are robust and durable. The inherent properties of aluminum allow these parts to withstand stress.

Applications of Aluminum Gravity Die Casting

Aluminum gravity die castings are used across several industries due to their versatility and reliability. Below are some key applications:

| Industry | Applications |

|---|---|

| Automotive | Engine blocks, transmission cases, and brackets |

| Aerospace | Aircraft components such as landing gear parts, housings |

| Electrical | Electrical enclosures, connectors, and terminals |

| Construction | Structural components, door handles, and hardware |

| Consumer Products | Kitchen appliances, furniture fittings, and accessories |

The Aluminum Gravity Die Casting Process at SB Allu Cast

At Shree Bhagyalaxmi Industries (SB Allu Cast), we follow a meticulous process for aluminum gravity die casting, ensuring every part meets the highest standards of quality and performance.

1. Pattern Design and Mold Creation

The first step in the process is designing the pattern or mold. Our engineering team works closely with clients to ensure that the mold design meets the desired specifications.

2. Die Preparation

The die, typically made from high-grade steel, is cleaned and prepared to receive the molten aluminum.

3. Melting and Pouring

Aluminum is heated in a furnace to its molten state. The temperature is carefully controlled to ensure optimal fluidity.

Why Choose Shree Bhagyalaxmi Industries (SB Allu Cast)?

Expertise and Experience

With years of experience in aluminum gravity die casting, Shree Bhagyalaxmi Industries (SB Allu Cast) has earned a reputation for delivering high-quality products. Our expert engineers and technicians are equipped with the knowledge and tools to handle even the most complex casting requirements.

Customization for Diverse Needs

We understand that every industry has unique requirements. Whether you need aluminum castings for automotive, aerospace, or construction applications, we can provide tailored solutions that meet your specifications.

Timely Delivery

At SB Allu Cast, we prioritize punctuality and reliability. We work hard to ensure that your aluminum gravity die castings are delivered on time, every time, without compromising quality.

Aluminum vs. Other Materials: Why Choose Aluminum Gravity Die Casting?

When compared to other materials like steel or plastic, aluminum offers several key advantages in die casting:

- Lightweight: Aluminum is significantly lighter than steel, making it ideal for applications where weight is a concern, such as in the automotive and aerospace industries.

- Corrosion Resistance: Aluminum naturally forms an oxide layer that protects it from corrosion, which makes it suitable for outdoor and high-humidity environments.

- Thermal and Electrical Conductivity: Aluminum is an excellent conductor of both heat and electricity, making it a preferred choice for electronic enclosures and heat exchangers.

- Recyclability: Aluminum is 100% recyclable, making it an environmentally friendly choice for sustainable manufacturing.

Conclusion: Quality Aluminum Die Castings at SB Allu Cast

At Shree Bhagyalaxmi Industries (SB Allu Cast), we are dedicated to providing high-quality aluminum gravity heavy die castings that meet the precise needs of our clients. With a strong commitment to excellence, state-of-the-art technology, and an experienced team, we are the ideal partner for all your aluminum casting requirements.

Get in Touch with Us Today

If you are looking for a trusted manufacturer of aluminum gravity die castings, contact Shree Bhagyalaxmi Industries (SB Allu Cast) in Ahmedabad, Gujarat today. Our team will be happy to discuss your project requirements and provide you with a customized solution that meets your needs.

Leave a Reply